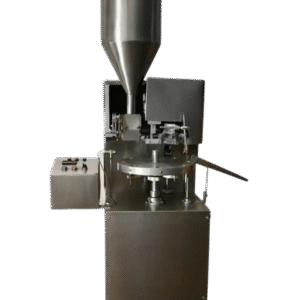

The Double Head Aluminum Tube Filling, Crimping & Coding Machine is a mechanically operated solution designed for high-speed, accurate, and hygienic tube filling applications. Built as per GMP standards, this machine is ideal for filling semi-viscous to viscous products like creams, gels, pastes, ointments, and adhesives into aluminum tubes. With its double-head setup, it offers a production output of up to 70 tubes per minute, making it perfect for pharmaceutical, cosmetic, food, chemical, and adhesive industries.

Salient Features

-

-

Double head design for higher productivity.

-

Mechanical operation ensures consistent performance and lower maintenance.

-

GMP-compliant structure with stainless steel 316 product contact parts.

-

Accurate filling with ±1% precision.

-

No Tube – No Fill system to avoid product wastage.

-

Adjustable filling volume from 5ml to 250ml.

-

Easy and quick changeover for different tube sizes.

-

Pneumatic tube clamping for smooth and secure handling.

-

Batch coding through embossing during the crimping process.

-

Compact footprint with user-friendly design.

-

Easy dismantling and cleaning for reduced downtime.

-

Technical Specification

| Parameter | Specification |

|---|---|

| Production Output | Up to 70 Tubes/Minute |

| Tube Diameter Range | 12mm to 50mm |

| Tube Length | Up to 250mm |

| Filling Volume Range | 5ml to 250ml (Adjustable) |

| Filling Accuracy | ±1% |

| Product Contact Parts | Stainless Steel 316 |

| Tube Holding System | Pneumatic |

| Drive System | Mechanical |

| Batch Coding System | Embossing during Crimping |

| Main Motor | 2 H.P., 380/440V, 3 Phase, 50 Hz |

| Air Consumption | 250 Liters/min at 6 Bar |

| Machine Dimensions | 1500mm (L) x 1000mm (W) x 1800mm (H) |

| Net Weight | Approx. 650 Kgs |

There are no reviews yet.